Robobi matakai biyu Fim da zaruruwa da jakunkuna Pelletizing Machine

Bidiyon samfur:

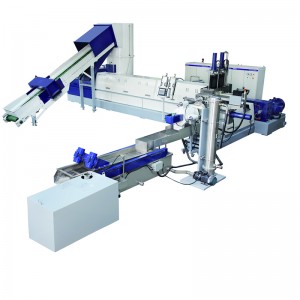

Hotunan Kayan aiki:

Kayan Aiki:

HDPE.

Foamed PE, EPS da XPS: Rolls, jaka, sheet, abinci akwati, 'ya'yan net, murfin

Yadi: PP fiber, raffia, siliki, yarn, jakar saka, jakar jumbo

Siffofin:

Wannan compactor hadedde tsarin pelletizing yana amfana da kayan da aka sake fa'ida ba tare da yankewa ba

Compacting samu sanye take da abin yanka bawuloli, waɗanda ake amfani da su sarrafa kayan gudun ciyar

Tsarin injin don shayar da ruwa ko iskar gas da yawa

Kyakkyawan matatar allo na ruwa mai ƙarfi tare da tsayayyen matsa lamba don rashin tsayawa, babu zubewa

Ajiye wuta tare da babban fitarwa (0.28kwh/kg)

Gabaɗaya tsarin aiki:

1.Belt conveyor canja wurin abu a cikin shredding compactor.

2.The interlock kula da tsarin tsakanin bel isar zuwa da shredding compactor tabbatar da ma'auni ciyar ba tare da narkewa compactor.

3.A kasan shredding compactor, akwai wani abun yanka guda daya.tare da ƙarfin centrifugal, kayan da aka sake fa'ida ana riga an yanke su ta cikin masu yankan jujjuyawa da masu yankan tsaye.

4.Bayan haka, abu yana shiga cikin degassing dunƙule daga gefen compactor.

5.With dunƙule dumama, filastik zama Semi-plastification abu.

6.Kuma a sa'an nan, Semi-roba abu samu a yanka a cikin pellets.

Babban Ma'aunin Fasaha:

| Samfura | ML75 | ML85/SJ90 | ML100/SJ120 | ML130/SJ140 | ML160/SJ180 | ML180/SJ200 |

| Diamita na dunƙule (mm) | 75 | Mataki na farko 85 Mataki na biyu 90 | Mataki na farko 100 Na biyu mataki 120 | Mataki na farko:130Mataki na biyu:140 | Mataki na farko:160Mataki na biyu:180 | Mataki na farko:180Mataki na biyu:200 |

| L/D | Mataki na farko: 26 zuwa 37 Mataki na biyu: 10 zuwa 15 | |||||

| Fitowa (kg/h) | 100-150 | 150-250 | 250-350 | 450-550 | 600-800 | 1000 |

Hotunan Inji:

Single dunƙule extruder

Mai sake amfani da mataki sau biyu extruder

Janar bayani:

| Sunan samfurin | ML |

| fitarwa | Filastik pellets / granules / resin / filastik albarkatun kasa |

| Kayan inji | belt conveyor, abun yanka compactor, babban extruder, pelletizing naúrar, sanyaya tsarin, silo, hukuma |

| Kayan sake yin amfani da su | PP/PE/LDPE/HDPE fim, jaka, fiber |

| Kewayon iya aiki | 100kg/h zuwa 1200kg/h |

| Hanyar ciyarwa | Mai jigilar kaya, tsarin tuki |

| Diamita na dunƙule | 75mm zuwa 200mm |

| Rufe L/D | 26 zu33 |

| Dunƙule albarkatun kasa | 38CrMoAl ko bimetallic |

| degassing | Degassing na halitta, vacuum degassing |

| Nau'in yanke | Hanyar pelleting a tsaye, cire tsiri pelletizing |

| Nau'in sanyaya | Ruwa sanyi, iska mai sanyi |

| ƙarfin lantarki | Musamman |

| Na'urori na zaɓi | Mai gano karfe, tsarin sanyaya ruwa, silo mai ciyarwa, tsarin girgiza |

| Lokacin bayarwa | 40 zuwa 60 kwanaki |

| Lokacin garanti | watanni 13 |

| Goyon bayan fasaha | Tsarin injin, shimfidar shigarwa, aikin injiniyan sabis na ketare |

| Takaddun shaida | CE/SGS/TUV/CO |

Don me za mu zabe mu?

A.PURUI yana da ƙwararrun masana'anta tun daga 2006. muna da sashen ƙirar mu na fasaha.Ana tsara kowane extruder bisa ga fasalin kayan aiki.

B.Power ceto tare da babban fitarwa

C.Lokacin garantin inganci shine watanni 12 tun lokacin da aka ƙaddamar da lissafin Lading.

D. Lokacin isarwa: 40 kwanakin aiki zuwa kwanaki 60

E.Ship nema kunshin

Shigar F.Machine yana cikin jirgi.Yana ɗaukar kimanin kwanaki 5 zuwa 7 tare da kammala lokaci ɗaya na shigarwa.Injiniya (masu) da aka ba su suna kula da horar da mai amfani da injin, aikin injin da hukumar.

Gabatarwar Kamfanin:

Chengdu PuRui Polymer Engineering Co. Ltd yana daya daga cikin manyan masana'antun na'urorin sake amfani da filastik, masu fitar da kaya, filastik granulator da kayan taimako masu dangantaka a kasar Sin.Mu filastik pelletizing tsarin ta musamman abũbuwan amfãni ne dunƙule zane, high fitarwa, mai kyau degassing da kyau tace sakamako.Layin wankin mu na filastik kamar na'ura mai juriya da kaifi mai kaifi, raka'a wanki, na'ura mai rarrabawa ko rarrabawa, tsarin bushewa, da tsarin marufi suna da ingancin sauti.

Injin sake yin amfani da filastik wani nau'in kayan aiki ne da ake amfani da shi don sake sarrafa sharar robobi zuwa cikin granules ko pellet waɗanda za a iya sake amfani da su wajen kera sabbin samfuran filastik.Na'urar yawanci tana aiki ta hanyar shredding ko niƙa dattin robobi zuwa ƙanana, sa'an nan kuma narkewa da fitar da shi ta hanyar mutu don samar da pellets ko granules.

Akwai nau'ikan na'urorin sake yin amfani da filastik daban-daban da kuma injunan granulating, gami da dunƙule guda ɗaya da tagwayen fiɗa.Wasu injinan kuma sun haɗa da ƙarin fasali kamar allo don cire ƙazanta daga sharar filastik ko tsarin sanyaya don tabbatar da ƙaƙƙarfan pellet ɗin da kyau.Injin wanki na kwalban PET, layin wanki na buhunan PP

Ana amfani da injinan sake yin amfani da robobi a masana'antu da ke haifar da ɗimbin sharar robobi, kamar marufi, motoci, da gini.Ta hanyar sake yin amfani da sharar filastik, waɗannan injinan suna taimakawa rage tasirin zubar da filastik da kuma adana albarkatu ta hanyar sake amfani da kayan da ba za a jefar ba.

Kayan aikin sake amfani da batirin Lithium wani nau'in kayan aiki ne da ake amfani da su don sake sarrafawa da kuma dawo da kayayyaki masu mahimmanci daga batir lithium-ion, waɗanda galibi ana amfani da su a cikin na'urorin lantarki kamar wayoyin hannu, kwamfutar tafi-da-gidanka, da motocin lantarki.Kayan aikin yawanci suna aiki ne ta hanyar wargaza batura zuwa sassan da ke cikin su, kamar su cathode da kayan anode, maganin electrolyte, da foils na ƙarfe, sannan kuma a ware su da tsarkake waɗannan kayan don sake amfani da su.

Akwai nau'ikan kayan aikin sake amfani da baturin lithium daban-daban, gami da hanyoyin pyrometallurgical, hanyoyin hydrometallurgical, da hanyoyin inji.Hanyoyin pyrometallurgical sun haɗa da sarrafa zafin jiki na batura don dawo da karafa kamar jan karfe, nickel, da cobalt.Hanyoyin ruwa na lantarki suna amfani da hanyoyin sinadarai don narkar da abubuwan baturi da dawo da karafa, yayin da hanyoyin injina suka haɗa da shredding da niƙa batura don raba kayan.

Kayan aikin sake amfani da batirin lithium yana da mahimmanci don rage tasirin muhalli na zubar da baturi da adana albarkatu ta hanyar dawo da karafa masu mahimmanci da kayan da za a iya sake amfani da su a cikin sabbin batura ko wasu kayayyaki.

Baya ga fa'idodin kiyaye muhalli da albarkatu, kayan aikin sake amfani da batirin lithium shima yana da fa'idojin tattalin arziki.Maido da karafa masu kima da kayan aiki daga batir da aka yi amfani da su na iya rage tsadar samar da sabbin batura, da kuma samar da sabbin hanyoyin samun kudaden shiga ga kamfanonin da ke da hannu wajen sake yin amfani da su.

Bugu da ƙari, karuwar buƙatar motocin lantarki da sauran na'urorin lantarki yana haifar da buƙatar ingantaccen masana'antar sake sarrafa baturi mai dorewa.Kayan aikin sake amfani da batirin lithium na iya taimakawa wajen biyan wannan buƙatu ta hanyar samar da ingantacciyar hanya mai tsada don maido da abubuwa masu mahimmanci daga batir ɗin da aka yi amfani da su.

Koyaya, yana da mahimmanci a lura cewa sake yin amfani da batirin lithium har yanzu sabon masana'antu ne, kuma akwai ƙalubalen da za a shawo kan su ta fuskar haɓaka ingantattun hanyoyin sake amfani da su.Bugu da ƙari, kulawa da kyau da zubar da sharar baturi yana da mahimmanci don guje wa haɗarin muhalli da lafiya.Don haka, dole ne a samar da ingantattun ƙa'idoji da matakan tsaro don tabbatar da alhakin kulawa da sake yin amfani da batirin lithium.